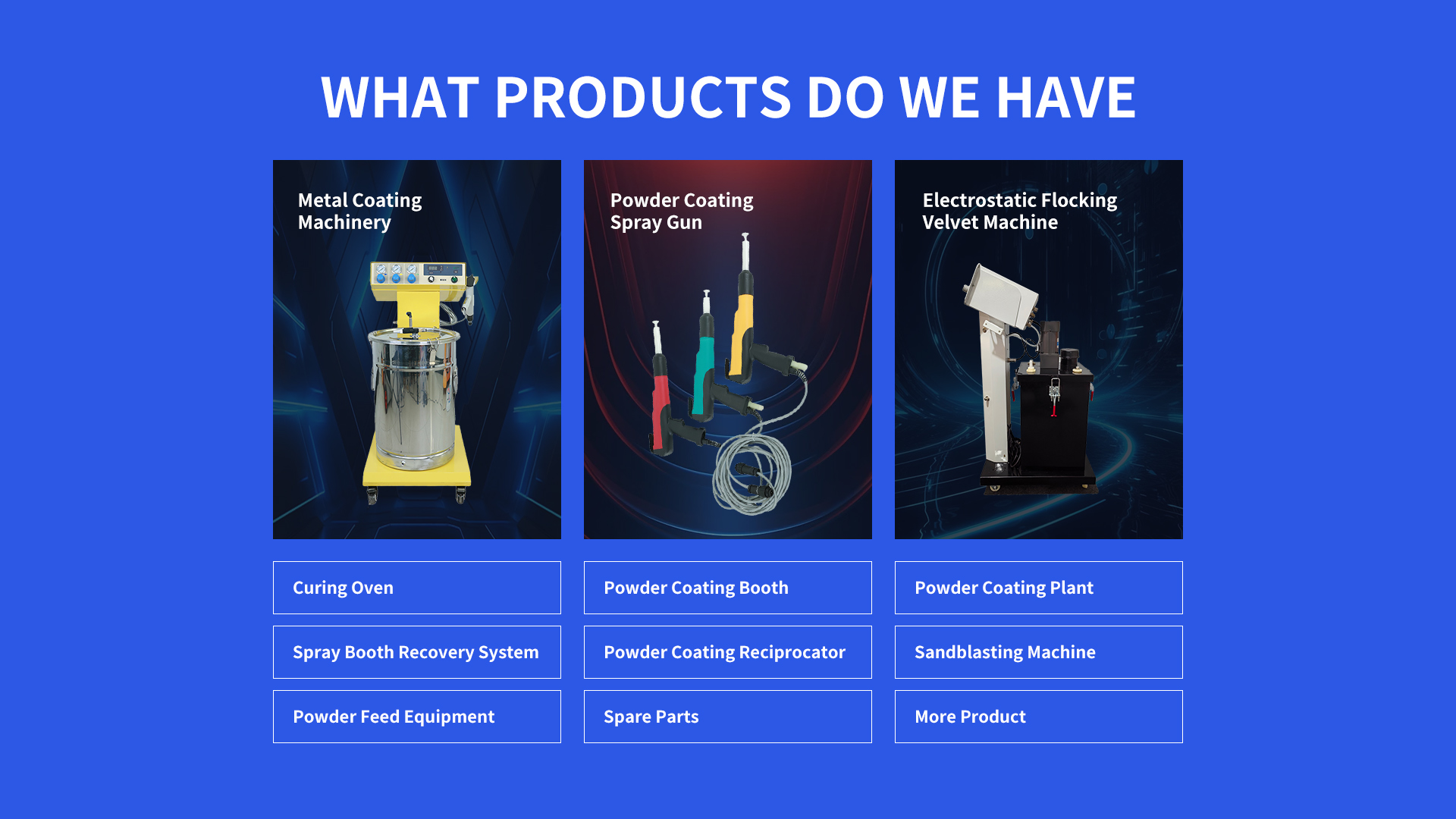

1. Reliant Powder Coating Equipment Overview and Components

Reliant Powder Coating Equipment delivers precision-engineered solutions for industrial coating needs. Core components include electrostatic spray guns (40–100 kV range), high-efficiency curing ovens (±5°F temperature accuracy), closed-loop powder recovery systems (95%+ efficiency), and PLC-controlled automation. The robust steel-frame design ensures durability, while modular configurations support scalability for diverse production demands.

2. Key Applications of Reliant Powder Coating Systems

Reliant Powder Coating Equipment dominates automotive manufacturing (engine parts, wheels), aerospace components (landing gear, brackets), and architectural metalwork (window frames, railings). Its superior adhesion (ASTM D3359 compliance) and UV-resistant finishes make it ideal for outdoor infrastructure, medical devices, and consumer electronics.

3. Cost Analysis of Reliant Powder Coating Equipment

Entry-level manual systems start at 8,000,whilefullyautomatedlinesexceed120,000. Mid-tier models (25,000–60,000) suit SMEs with features like infrared curing and 80% powder reuse rates. ROI is achieved within 18–24 months via reduced material waste and energy consumption (30% lower than traditional methods).

4. Operational Best Practices for Reliant Powder Coating Equipment

Pre-treatment is critical: degrease surfaces using alkaline cleaners and apply phosphate conversion coatings. Set spray distance at 6–10 inches for uniform coverage. Maintain 70% humidity control during curing to prevent defects. Conduct daily nozzle inspections and calibrate voltage weekly for peak performance.

5. Selecting Reliant Powder Coating Equipment: Technical Criteria

Prioritize production speed (sq. ft./hour), substrate compatibility (steel, aluminum, MDF), and oven capacity. Opt for ISO 9001-certified models with integrated IoT diagnostics. Verify CE/OSHA compliance and assess vendor technical support for troubleshooting and spare parts.

6. Safety Protocols for Reliant Powder Coating Operations

Implement NFPA 33-compliant ventilation systems to mitigate combustible dust risks. Use NIOSH-approved respirators (N95+) and anti-static footwear. Install ground fault circuit interrupters (GFCIs) and conduct biannual electrostatic safety audits. Store powders in fire-rated cabinets away from ignition sources.

7. Engineering Advantages of Reliant Powder Coating Systems

Reliant’s patented vortex recovery technology reduces overspray by 40%, while dual-stage curing ovens cut energy use by 25%. Ergonomic spray gun designs minimize operator strain, and cloud-based monitoring enables real-time process optimization.

8. Reliant Powder Coating Equipment FAQs

Q: What is the lifespan of Reliant powder coating machinery?

A: With proper maintenance, industrial systems operate 10–15 years.

Q: Can Reliant handle high-volume automotive coating?

A: Yes, automated lines process 500+ parts/hour with ≤2% defect rates.

Q: Are Reliant systems compatible with metallic powders?

A: Advanced tribo-charging guns support metallic and polyester blends.

Q: How does Reliant ensure environmental compliance?

A: Zero-VOC powders and 99% HEPA filtration meet EPA standards.

Q: What training is provided for Reliant equipment?

A: Vendors offer on-site certification programs for operators and technicians.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com